Featured Quizzes

User Quizzes

Create Quiz

Data and Charts

Badges and Games

About JetPunk

JetPunk Shop

Dark Mode

Texas Basic Waste Water Operations Ch#08 Activated Sludge Process

Take the test..... duh.......

Study questions for the class D waste water license.

Info source: TEEX infrastructure training & safety institute basic waste water operations resource book Module #08 Activated Sludge Process 2023.

Rate:

Last updated: September 29, 2023

You have not attempted this quiz yet.

More quiz info >>

| First submitted | September 29, 2023 |

| Times taken | 9 |

| Average score | 66.7% | Report this quiz | Report |

10:00

The quiz is paused. You have remaining.

Scoring

You scored / = %

This beats or equals

% of test takers

also scored 100%

The average score is

Your high score is

Your fastest time is

Keep scrolling down for answers and more stats ...

1.

The five components of the activated sludge process are the oxygen supply system, aeration tank, clarifier, return sludge system, and waste sludge system.

True

✓

False

✓

There are five primary components of the typical activated sludge process, oxygen supply, aeration tank, clarifier, return activated sludge, and waste sludge.

2.

Mixed liquor is the mixture of raw wastewater and microorganisms.

True

✓

False

✓

In the aeration tank, the raw wastewater is aerated and mixed with the microorganisms. The mixture of raw wastewater and microorganisms is called mixed liquor.

3.

In the clarifier, the biological solids separate by gravity settling.

True

✓

False

✓

In the secondary clarifier, solids settle by gravity. NTOE: since the reference is one sentence id like to add the following: Water at sea level has a specific gravity of 1, the grit in wastewater has a specific gravity in the range of 1.5-2.7, and the organic matter in wastewater has a specific gravity around 1.02. In both primary and secondary clarifiers settling happens due to decreased flow speed not being able to keep entrained solids in suspension, and a difference in density which causes a difference in specific gravity. Anything with a specific gravity greater than one will sink to the bottom due to the greater pull of gravity compared to water while anything with a specific gravity less than one will be buoyant enough to float.

4.

The settled biological solids accumulate in the clarifier, then are always wasted from the

process.

True

✓

False

✓

Settled solids (microorganisms) accumulate in the clarifier and are continuously returned to the aeration tank to reseed it. Waste sludge (wasting) removes excess solids, inert solids, and old or dead solids from the system. Removing solids consistently keeps the process balanced. Ignoring solid volume leads to poor operation and permit violation. Wasted sludge is sent to a digester or dewatering unit.

5.

Wasting removes excess solids, inert solids, and old or dead solids from the

system.

True

✓

False

✓

Settled solids (microorganisms) accumulate in the clarifier and are continuously returned to the aeration tank to reseed it. Waste sludge (wasting) removes excess solids, inert solids, and old or dead solids from the system. Removing solids consistently keeps the process balanced. Ignoring solid volume leads to poor operation and permit violation. Wasted sludge is sent to a digester or dewatering unit.

6.

The aeration tank should be observed weekly for a uniform aeration pattern, low amount of light colored foam, mild, earthy odor, and medium brown color.

True

✓

False

✓

The aeration tank should be monitored >daily< for uniform pattern, a low amount of light colored foam, and a mild, earthy odor. The mixture should be medium brown in color.

7.

The clarifier should have very little scum, a sludge blanket in the bottom 1/4 of the clarifier depth, uniform weir flow, rising solids, and turbid supernatant.

True

✓

False

✓

The clarifier should be observed daily for several indicators. There should be very little scum. The sludge blanket should be no more than 1/4 of the clarifier depth. There should be uniform weir flow. >Few rising solids should be visible<. Finally, the clarifier overflow should be clear*. NOTE:* this question is asking about a secondary clarifier for which the effluent should be clear while primary clarifier effluent is light or dark gray due to the unprocessed BOD carried over to secondary treatment methods.

8.

Process control parameters include dissolved oxygen, quantity and quality of solids, return rate, and wasting rate.

True

✓

False

✓

Factors influencing the activated sludge process are called control parameters. Five control parameters are Dissolved Oxygen (DO), solids quantity, solids quality, return rate, and wasting rate. An activated sludge plant will not operate effectively without these operator controls. Operators control aeration and mixing by maintaining the efficient use of the aeration equipment. Return activated sludge (RAS) rates may be controlled by adjusting pumping equipment or telescoping valves to achieve a desired rate of return. Operators may control wasting with timely removal of excess, dead, or inert solids from the system.

9.

Normally, DO should be kept between 20 and 40 mg/L.

True

✓

False

✓

r. Normally, keep DO between 2 and 4 mg/L. Keep a minimum of 2 mg/L DO to maintain the health of the aerobic microorganisms. If the organic load on the plant is high, increase DO levels. Aerobic organisms quickly deplete oxygen when the organic load is high. A plant under low organic load can operate with less dissolved oxygen than a plant under high organic load.

10.

At least 1 mg/L DO should be kept in the aeration basin to maintain the health of the

anaerobic microorganisms.

True

✓

False

✓

r. Normally, keep DO between 2 and 4 mg/L. Keep a minimum of 2 mg/L DO to maintain the health of the >aerobic< microorganisms. If the organic load on the plant is high, increase DO levels. Aerobic organisms quickly deplete oxygen when the organic load is high. A plant under low organic load can operate with less dissolved oxygen than a plant under high organic load.

11.

The primary purpose of returning sludge is to have enough ________ in the aerator to match the food supply

water

✓

microorganisms

✓

BOD

✓

air

✓

The primary purpose of returning sludge is to have enough microorganisms in the aerator to match the food supply. Adjust return rates to produce the desired F/M ratio. Small plants often keep return rates constant. Large plants, particularly those with tapered aeration, can plug flow or step-feed aerators; adjust return rates throughout the day. Adjust return rates to maintain proper blanket depth. Keep the blanket in the bottom 1/4 of the clarifier depth. If the blanket is too high or the mixed liquor is too thin, increasing the return rate may help.

12.

If the ________ loading on the plant is high, DO levels should be increased.

organic

✓

inorganic

✓

hydraulic

✓

all of the above

✓

If the organic load on the plant is high, increase DO levels. Aerobic organisms quickly deplete oxygen when the organic load is high. A plant under low organic load can operate with less dissolved oxygen than a plant under high organic load.

13.

A simple method indicating when to waste is the ________.

sludge volume index

✓

mixed liquor suspended solids

✓

30-minute settling test

✓

F/M ratio

✓

Wasting is based on the amount of solids in the system, solids quality, effluent quality, and organic loading. Two widely used parameters that indicate the quantity of solids in the system are the 30-minute settling tests (settleometer) and the Mixed Liquor Suspended Solids (MLSS). Also, F/M ratio, MCRT, and microscopic examination are good indicators of wasting requirements. Keep the information on trend charts for a visual record.

14.

________ are the smallest, most numerous, and most important of the activated sludge

microorganisms.

Protozoa

✓

Fungi

✓

Rotifers

✓

Bacteria

✓

Bacteria are the smallest, most numerous, and most important microorganism. They are single celled and readily adapt to the plant environment. They stabilize most of the organic matter. Bacteria are dispersed, floc-forming, or filamentous. Activated sludge usually has a mixture of these, but floc-formers must dominate for the sludge to settle properly. Too many filamentous organisms cause the floc to be fluffy and settle very slowly, which results in bulking sludge (a serious problem). Bulking sludge occupies more space than healthy sludge and can flow out of the clarifier, causing high effluent solids. Causes of bulking are complex and correction can be difficult.

15.

________ settles gently and uniformly, compacts slowly, and has sharp edges like a sponge.

Quality sludge

✓

Old sludge

✓

Young sludge

✓

Bulky sludge

✓

Quality sludge settles gently and uniformly, compacts slowly, and has sharp edges like a sponge. Normal colors are light brown, golden brown, or brown. NOTE: "sharp edges like a sponge" means there will be a clear demarcation between the sludge and the water in a settling test. ||| Under-aerated sludge is dark brown to black with a septic odor. It produces a dark, cloudy supernatant (clear water layer above the sludge), and poor effluent. ||| Old sludge settles rapidly. Initially, it leaves a cloudy, ashen supernatant, but the supernatant usually clears within the detention time of the clarifier. It is dark brown, but has no septic odor. Pin floc and ash indicate old sludge. Sludge containing excess solids is usually old, but settles slowly. ||| Young sludge settles very slowly and may require an hour to form supernatant. It has a dispersed, fluffy appearance. Straggler floc may be in the supernatant. Young sludge is gray to light brown. ||| Bulky sludge settles very slowly or not at all. It may overflow with the treated effluent. However, if supernatant forms, it is clear. Bulking sludge is usually darker than young sludge. Bulking sludge is caused by nutrient deficiency, low DO, low pH, high sulfides, or toxic waste. It is a common problem and often difficult to correct.

16.

The ________ modification of the activated sludge process has no primary clarifier, no

digester, 24-hour aeration time, a low F/M ratio, and complete nitrification.

conventional process

✓

extended aeration

✓

contact stabilization

✓

none of the above

✓

This question is referencing Table 8.1: Conventional Activated Sludge, Table 8.3: Contact Stabilization, and Table 8.4: Extended Aeration in the textbook. The conventional process does have a primary clarifier, and contact stabilization has a lower aeration time and incomplete nitrification. There are other differences but these are the ones that stick out to me.

17.

The ________ modification has no return sludge and the aeration tank is used as the

clarifier.

centennial batch reactor

✓

sequential box reactor

✓

sequential batch reactor

✓

sequential batch retractor

✓

This is a fill-and-draw process in which aeration and sedimentation are done in the same tank, requiring no return sludge from a separate clarifier. Improvement in automatic control and aeration equipment recently perfected this process, but Sequencing Batch Reactor (SBR) plants operated from 1914 to1920 nationwide. The process has five steps controlled by timers: (1) Fill (2) Aerate (3) Settle (4) Decant (5) Idle. NOTE: only one of the choices offered actually exist and the same answer was not offered twice so i hope you read carefully.

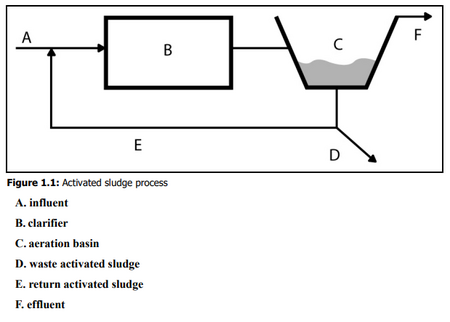

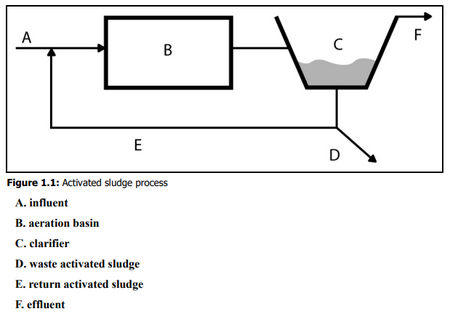

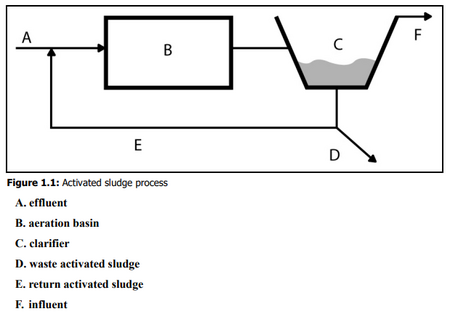

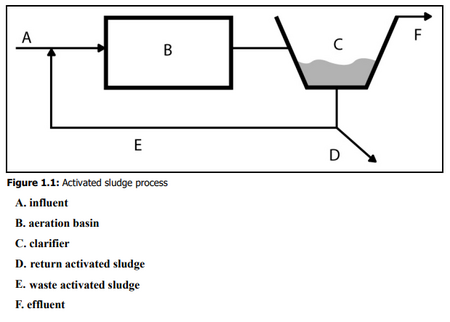

18.

Select the correctly labeled diagram below.

✓

✓

✓

✓

✓

✓

✓

✓

NOTE: the diagram does not include primary clarifiers, air being pumped into the bottom of the aeration basin (B) from an outside system, or valves/pumps

Comments

No comments yet

New and Popular

Save Your Progress

Texas Basic Waste Water Ops for class D license review

Quiz series by Mandaris

...

Copyright H Brothers Inc, 2008–2024

Contact Us | Go To Top | View Mobile Site