Featured Quizzes

User Quizzes

Create Quiz

Data and Charts

Badges and Games

About JetPunk

JetPunk Shop

Dark Mode

Texas Waste Water Treatment Ch#15.4 Activated Sludge

Take the test..... duh.......

Study questions for the class C waste water license.

Info source: TEEX infrastructure training & safety institute waste water treatment resource book Module #15.2 Primary Clarifier 2023.

Rate:

Last updated: January 17, 2024

You have not attempted this quiz yet.

More quiz info >>

| First submitted | December 14, 2023 |

| Times taken | 2 |

| Average score | 28.6% | Report this quiz | Report |

15:00

The quiz is paused. You have remaining.

Scoring

You scored / = %

This beats or equals

% of test takers

also scored 100%

The average score is

Your high score is

Your fastest time is

Keep scrolling down for answers and more stats ...

1.

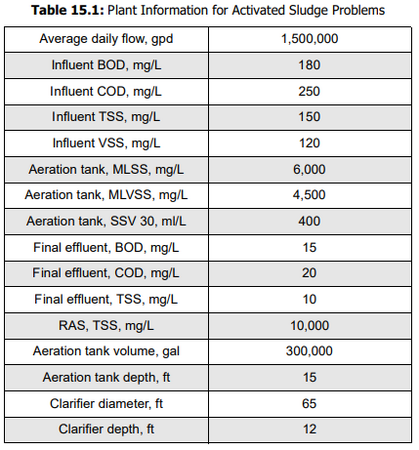

Given the information about a plant present in Table 15.1, calculate the operating information asked for below.

✓

✓

Choose this answer for free points

✓

i just needed a way to insert the

✓

given data for the following questions.

✓

2.

Determine F/M Ratio.

0.2 F/M

✓

0.3 F/M

✓

1.2 F/M

✓

0.5 F/M

✓

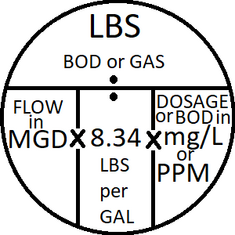

TLDR: F/M = (MGD X 8.34lb/gal X mg/L BOD) / (MG aerated X 8.34lb/gal X mg/L MLVSS) = (1.5MGD X 8.34lb/gal X 180mg/L BOD) / (0.3MG X 8.34lb/gal X 4,500mg/L) = 0.2 F/M! ||| EXPLANATION: The TLDR formula comes directly from the answer key but to understand its derivation you have to understand that the "8.34" conversion factor is BOTH what one gallon of water weighs AND how much one milligram of a substance in 1 liter of water weighs in pounds per MILLION gallons. since we are using it for the second reason it is vitally important that the volumes are given in MILLIONs of gallons or you will get the wrong answer. (1mg/L = 0.000008345... lbs/gal = 8.34 lbs/million gallons) Further, the Food to Microorganism Ratio is the ratio of the amount of food applied per day to the microorganisms in the aeration tanks. BOD (or COD if used to aproximate BOD) is used as a measure of food and the Mixed Liquor Volatile Suspended Solids(MLVSS) is used as a measure of the microorganism cell mass. The F/M ratio is calculated by dividing the pounds of incoming BOD (food) by the pounds of MLVSS (microorganisms) in the aeration tank. The portion of the Mixed Liquor Suspended Solids(MLSS) that is actually eating the incoming food(in terms of COD & BOD) is referred to as the MLVSS. The volatile solids concentration in a sample of mixed liquor will consist mostly of microorganisms and organic matter. As a result, the volatile solids concentration of mixed liquor is approximately equal to the amount of microorganisms in the water and can be used to determine whether there are enough microorganisms present to purify the water. Drying a sample with 105° C applied in an oven gives the value of MLSS then further drying with 550° C in a furnace gives the value of MLVSS. This leaves us only one value left unexplained and that is "MG aerated" which is the capacity of your basin in MILLIONS of gallons. we need this volume to determine the total number of pounds of microorganisms there are in the entire basin so that we can use it to devide the total amount of food supplied to that basin. Now that we know what all our needed values are we can look at the given data set and start plugging numbers into our equation. To start with we want to know how much food is coming in per day so we multiply the average daily flow in MGD (MGD = gpd / 1,000,000 = 1,500,000 / 1,000,000 = 1.5MGD) by the influent BOD concentration in that flow (180mg/L) and our 8.34lbs/MG conversion factor and save that number for later. (yes this is technically a typo in TEEX's textbook and answer key but now you know why they got it mixed up) (F = MGD X 8.34lbs/MG X influent BOD = 1.5MGD X 8.34lbs/MG X 180mg/L = 2551.8 lbs per day) Now we can figure out the microorganism mass by multiplying the aeration tank volume in MG (MG = aeration tank volume / 1,000,000 = 300,000 / 1,000,000 = 0.3MG) by our 8.34lbs/MG conversion factor and our aeration tank MLVSS (M = MG aerated X 8.34lbs/MG X MLVSS = 0.3MG X 8.34lbs/MG X 4,500mg/L = 11259lbs) Finally, we divide our food value (F) by our microorganism value (M) to yeild our F/M ratio. (F/M ratio = F/M = (MGD X 8.34lb/gal X mg/L BOD) / (MG aerated X 8.34lb/gal X mg/L MLVSS) = (1.5MGD X 8.34lb/gal X 180mg/L BOD) / (0.3MG X 8.34lb/gal X 4,500mg/L) = 2551.8lbs/day / 11259lbs = 0.2266453503... = 0.2!)

3.

Determine SVI.

88.9

✓

150

✓

70

✓

66.7

✓

TLDR: SVI = (30 min settleable X 1,000) / MLSS = (400ml/L X 1,000) / 6,000mg/L = 400,000 / 6,000 = 66.7! ||| EXPLANATION: The sludge volume index (SVI) may be calculated from the results of the 30-minute settling test(SSV 30) and the MLSS test. The SVI indicates the number of mL that contain 1 gram of solids. SVI helps the operator know if the sludge is bulky. Numbers between approximately 70 and 150 are typical for healthy activated sludge. Above 150, the sludge gets increasingly bulky and harder to settle. Below 70, the floc does not clump adequately and more suspended solids remain entrapped by the floc as it settles rapidly. From the table of given values start by dividing "aeration tank, SSV 30" by "aeration tank, MLSS" then multiply by 1,000. (SVI = (SSV 30 / MLSS) X 1,000 = (400ml/L / 6,000mg/L) X 1,000 = 0.06666667 X 1,000 = 66.666666666667 = 66.7!)

4.

Determine Gould Sludge Age.

3 HRS

✓

8 DAYS

✓

20 MIN

✓

13.3 DAYS

✓

TLDR: GSA = (MG aerated X 8.34lb/MG X mg/L MLSS) / (MGD X 8.34lb/MG X mg/L TSS inf) = (0.3MG X 8.34lb/MG X 6,000mg/L) / (1.5MGD X 8.34lb/MG X 150mg/L) = 8 days GSA! ||| EXPLANATION: Gould Sludge Age(GSA) estimates how long, in days, a pound of solids stays in the aerator. The age of the sludge can be used to determine what needs to be removed from the system so that the process stays in balance. GSA is calculated by dividing the total pounds of TSS in the aerator by pounds of TSS entering the aerator as raw influent each day. The values we will need from the table are influent total suspended solids (influent TSS), aeration tank mixed liquor suspended solids (aeration tank MLSS), average daily flow in MGD (Average daily flow in gpd divided by 1,000,000), and the aeration tank volume in MG (aeration tank volume in gal divided by 1,000,000). Similar to the detention time calculations we will be mathematically determining how long it will take the incoming suspended solids to completely displace the existing suspended solids in the basin. To start we will figure out how many poinds of suspended solids are in the aerator basin by multiplying our solids concentration per gallon by the number of gallons in the basin and saving that number for later. (MLSSbasin = MG aerated X 8.34lb/MG X mg/L MLSS = (300,000 / 1,000,000)MG X 8.34lb/MG X 6,000mg/L = 0.3MG X 8.34lb/MG X 6,000mg/L = 15,012lbs) Now we need to figure out how much is coming in every day by multiplying the incoming number of MILLIONS of gallons per day by the amount of solids in each gallon coming in. (TSSin = MGD X 8.34lb/MG X mg/L TSS inf = (1,500,000 / 1,000,000)MGD X 8.34lb/MG X 150mg/L = 1.5MGD X 8.34lb/MG X 150mg/L = 1876.5lb/day) Finally we divide how much we have by how quickly we are replacing it to determine how many days it will take to replace the entire amount. (GSA = MLSSbasin / TSSin = 15,012lbs / 1876.5lbs/day = 8days!)

5.

What is the desired return rate in gpm?

1,895.6 GPM

✓

1,092.5 GPM

✓

1,562.5 GPM

✓

2,002.5 GPM

✓

TLDR: RAS = (Flow X MLSS) / (RAS TSS - MLSS) = (1.5MGD X 6,000mg/L) / (10,000 - 6,000)mg/L = 9,000MGDmg/L / 4,000mg/L = 2.25MGD | gpd = MGD × 1,000,000 gal/MG = 2,250,000gpd | gpm = gpd / 1,440 min/day = 2,250,000gpd / 1,440min/day = 1,562.5gpm! ||| EXPLANATION: In a broad sense you want all non-water mass expelled from the aeration basin to be returned to the start of the aeration process so that all of that solid waste can be fully digested and the overall level of sludge in the secondary clarifier remains constant. I am told this question is something you are very unlikely to see on a graded evaluation. In my textbook the reference for this question is on page 8-17 below figure 8.11 where it talks very briefly about how they derived this formula. Unfortunately they dont go into enough detail for my meagre math skills to understand the derivation process so if anyone can explain and show the derivation process in the comments i hereby promise to think kind thoughts about you for at least five minutes. They start with a mass balance premise (pounds entering clarifier = pounds returned to aeration tank) (Q + RAS) × MLSS × 8.34 lb/gal = RAS × RSS × 8.34 lb/gal then they state they rearrange the second half of the balance to isolate RAS rate as the unknown variable to arrive at this equation RAS = (Flow X MLSS) / (RAS TSS - MLSS) from this its pretty easy to pick out the values you need from the table of given data. it seems we are dividing the flow rate of effluent at a solids concentration equal to that found in the basin by the concentration of solids we want to return and solving for the pumping rate we need to return it per day. (RAS = (Flow X MLSS) / (RAS TSS - MLSS) = (1.5MGD X 6,000mg/L) / (10,000 - 6,000)mg/L = 9,000MGmg/DL / 4,000mg/L = 2.25MGD) Then we need to convert down our resulting flow rate per day to a per minute level to asnwer the question asked. We start by converting our resulting MGD to GPD by multiplying by one million. (gpd = MGD × 1,000,000 gal/MG = 2,250,000gpd) Finally we further convert our flow in gpd to flow in gpm by dividing our flow per day by the number of minutes in that day. (gpm = gpd / 1,440 min/day = 2,250,000gpd / 1,440min/day = 1,562.5gpm!)

6.

Determine overall plant efficiency in percent BOD reduction.

91.6%

✓

8.3%

✓

98.7%

✓

15%

✓

TLDR: % reduction = ((In-Out) / In) X 100 = ((180-15)mg/L / 180mg/L) X 100 = 91.6%! ||| EXPLANATION: There are only two values that we need from the table the BOD coming in wiht your raw water(Influent BOD, mg/L) and the amount remaining after the treatment process(Final effluent, BOD, mg/L). what we want to know is if the influent BOD is 100% what percentage of BOD is removed by the treatment process. First, take the amount of BOD that came in and subtract the BOD left after the treatment process to arrive at the total amount of BOD removed durring the treatment process.(BOD removed = Influent BOD - Final effluent BOD = (180 - 15)mg/L = 165 mg/L) then divide the amount removed by how much came in to determine what fraction of the incoming BOD was removed. (Fraction BOD removed = BOD removed / Influent BOD = 165 mg/L / 180 mg/L = 0.91666666666666) Finally, multiply the result by 100 to convert to a percentage. (% reduction = Fraction BOD removed X 100 = 0.91666666666666 X 100 = 91.667%!)

7.

Determine aeration tank detention time in hours.

4.8 HOURS

✓

3.2 HOURS

✓

1.92 HOURS

✓

2.42 HOURS

✓

TLDR: Flow: Total = Influent + Return = 1.5MGD + 2.25MGD = 3.75MGD| gpd = MGD X 1,000,000gal/MG = 3.75MGD X 1,000,000gal/MG = 3,750,000gpd| gph = gpd / 24hrs/day = 3,750,000gpd / 24hrs/day = 156,250gph| DThrs = Capacity / Flow in gph = 300,000gal / 156,250gph = 1.92hrs! ||| EXPLANATION: This looks like a normal detention time calculation and anyone that gets it wrong will i suspect simply have neglected to include the return flow in the flow calculations. Since this is specifically for an aeration basin and not a clarifier or simple digester flow returned to the basin from the secondary clarifier calculated in question 4 must be included or it will not accurately represent flow through the aeration basin. (Total Flow in MGD = Influent MGD + Return MGD) This total flow will need to be converted down to gph in order to meet the question requirements of detention time in hours instead of fractions of a day but i will include that in the final combined equation. (DThrs = basin capacity in gal / Total flow in gph = 300,000gal / ((Total flow in MGD X 1,000,000gal/MG) / 24hrs/day)gph = 300,000gal / (((Influent MGD + Return MGD) X 1,000,000gal/MG) / 24hrs/day)gph = 300,000gal / (((1.5MGD + 2.25MGD) X 1,000,000gal/MG) / 24hrs/day)gph = 300,000gal / 156,250gph = 1.92hrs!)

Comments

No comments yet

New and Popular

Save Your Progress

Texas Waste Water Treatment Study Guide

Quiz series by Mandaris

...

Copyright H Brothers Inc, 2008–2024

Contact Us | Go To Top | View Mobile Site