Featured Quizzes

User Quizzes

Create Quiz

Data and Charts

Badges and Games

About JetPunk

JetPunk Shop

Dark Mode

Texas Waste Water Treatment Ch#08 Activated Sludge Process

Take the test..... duh.......

Study questions for the class C waste water license.

Info source: TEEX infrastructure training & safety institute waste water treatment resource book Module #8 Activated Sludge Process 2023.

Rate:

Last updated: January 17, 2024

You have not attempted this quiz yet.

More quiz info >>

| First submitted | July 1, 2023 |

| Times taken | 45 |

| Average score | 73.3% | Report this quiz | Report |

10:00

The quiz is paused. You have remaining.

Scoring

You scored / = %

This beats or equals

% of test takers

also scored 100%

The average score is

Your high score is

Your fastest time is

Keep scrolling down for answers and more stats ...

1.

The purpose of return activated sludge is to reseed the biological reactor with treatment

microorganisms.

False

✓

True

✓

Healthy activated sludge is composed of a large variety of different microorganisms that clump together in tiny fluffy solids called floc. When in optimum condition, the brown floc settles gently and uniformly and produces a mat that traps and collects smaller particles as it settles. Above the settling solids is left a clear water layer that flows over the weirs of the clarifier.

2.

Good activated sludge is gray and settles rapidly, leaving a clear supernatant.

True

✓

False

✓

Good activated sludge settles uniformly and leaves a clear supernatant.

3.

The clarifier should concentrate the mixed liquor solids at least two times.

False

✓

True

✓

During normal operations, the clarifier will concentrate sludge, making it two to four times denser than the solids concentration of the mixed liquor, which may provide return sludge with a concentration of 2,000–10,000 mg/L or 0.2%–1.0% of total solids.

4.

An airlift sludge return pump should be turned on each morning to return activated sludge to the aeration tank.

True

✓

False

✓

Pumps continually send RAS to the aeration tank, reseeding the biological reaction in the aeration tank and removing accumulating sludge from the clarifier. No matter what method is used, return pumps must be able to provide 50%–150% of the raw influent flow. Activated sludge systems use telescoping valves (which incrementally open and close) or pumping rates (which can be increased or decreased) to control the rate at which sludge is removed from the bottom of the clarifier (called underflow). Underflow is sent into the solids return systems.

5.

The reason for wasting solids from an activated sludge system is to remove excess

biological solids, inert solids, and old or dead microorganisms.

False

✓

True

✓

Operators should follow a routine wasting schedule to remove excess biological solids, inert solids from the system, and old or dead biological solids. A planned, consistent program of removing solids keeps the activated sludge process balanced. Ignoring the need to waste solids always leads to poor operating conditions, which will eventually result in permit violations.

6.

F/M ratio, sludge age, and settling tests provide valuable operating information to

determine proper plant oxygen levels.

True

✓

False

✓

F/M ratio compares how much food is available to the amount of treatment microorganisms, sludge age estimates how long, in days, a pound of solids stays in the aerator, and settling tests provide information on sludge quality. Dissolved oxygen(DO) must be present in sufficient concentration (about 2–3 mg/L) in all parts of the aeration tank and is determined, monitored, and controlled via DO sensors.

7.

Oxygen levels, wasting rates, sludge quality, return rates, and aerator solids levels are

important control parameters for activated sludge plants.

False

✓

True

✓

The conscientious operator will obtain as much information as possible from laboratory tests and visual observations. The operator will study the information to evaluate the following: • Aeration effectiveness • Mixing effectiveness • Return rates • Wasting rates

8.

Dissolved Oxygen(DO) should be kept at very high levels in the aeration tank.

True

✓

False

✓

Levels will normally be kept between 2 mg/L and 4 mg/L. Operators should keep at least 2 mg/L DO to maintain the health of the aerobic microorganisms.

9.

Dissolved Oxygen(DO) levels in activated sludge plants should be kept at the 2–4 mg/L level with 1 mg/L

minimum.

False

✓

True

✓

Operators should keep at least 2 mg/L DO to maintain the health of the aerobic microorganisms, but less than 4 mg/L to limit excess process costs. A DO level of <1 mg/L will encourage the growth of facultative and anaerobic bacteria.

10.

Air requirements in an activated sludge process are governed by the organic loading on the plant.

True

✓

False

✓

Simply stated, a plant that is above its designed organic load will require higher dissolved oxygen levels than a plant that has a low organic load. Good DO control is tied to return sludge control and wasting rates. DO levels are adjusted by increasing or decreasing aeration rates to maintain the desired DO levels throughout the basin. If either the return rate or wasting rate is not properly adjusted, excess biological solids in the system may use up so much DO that adequate DO cannot be achieved by increasing aeration rates. On the other hand, if wasting is excessive or return is inadequate, there may be an insufficient amount of microorganisms to treat the incoming waste and DO levels will be excessively high.

11.

Sludge bulking in an activated sludge plant can be easily corrected.

False

✓

True

✓

The settling of activated sludge in a final clarifier depends on physical, specifically hydraulic, and biological factors. Unfavorable conditions will result in poor settling of solids, or “bulking,” where sludge goes over the weir with the treated effluent. Determining the cause of bulking and the best correction method can be complicated and man-hour intensive. Also, saying your job is easy is never good for job security.

12.

Rising sludge and gas bubbles can be caused by denitrification in the final

clarifier.

True

✓

False

✓

The problem of rising sludge differs from sludge bulking in that the sludge first settles well but then rises in chunks and floats on the surface of the final clarifier. Chunks of rising sludge vary in size, some becoming as large as a basketball. Sludge rising is associated with the process of nitrification-denitrification (see nitrogen cycle). As released nitrogen gas becomes trapped in the clarifier sludge blanket, it causes the sludge to rise. Floating sludge causes an increase in effluent Total Suspended Solids(TSS) and Biochemical Oxygen Demand(BOD).

13.

The 30-minute settling test gives the operator a visual check on sludge quality.

False

✓

True

✓

The 30-minute settling test is a key visual indicator of sludge quality and should be performed frequently. It is a simple test performed on a well-mixed, representative sample of mixed liquor taken as it leaves the aeration basin. This sample is allowed to settle in a glass or plastic settling container, such as a graduated cylinder, glass beaker, settleometer, or simply a quart mason jar. The operator observes the settling test and records the results based on what volume of sludge settled out in the given time..

14.

The endogenous growth phase occurs when there is more food than the microorganisms can consume.

True

✓

False

✓

Endogenous growth phase: When the food supply becomes inadequate, bacteria use their own organic cell material as food.

15.

Temperature has no effect on the activity of microorganisms in the activated sludge process because wastewater is always warm.

False

✓

True

✓

Temperature is important and greatly determines the number of microorganisms needed. As the temperature rises, microorganisms will be more active and will increase in numbers. A decrease in temperature will slow down the growth of the microorganisms. As a result, more sludge could be returned in cooler weather.

16.

A conventional activated sludge process has primary clarifiers that remove about l0%–20% of the organic load.

True

✓

False

✓

In the conventional process, the activated sludge unit is preceded by primary treatment, which will remove 30%–40% of the organic load.

17.

In the extended aeration process, air blowers or aerators normally run continuously to

provide the oxygen needed unless the plant is small and underloaded

organically.

False

✓

True

✓

When the loading on extended aeration plants is low, timers can be used to cycle the plant on and off. If run on a part-time basis, BOD reduction can be expected in the 90%–95% range.

18.

Complete mix plants will not handle shock loads as well as other activated sludge

modifications.

True

✓

False

✓

Complete mix plants are a common variation of the activated sludge process. It has the advantage of quick dilution of the incoming flow, which can reduce the effects of shock loads and toxic materials. It also results in low concentrations of organic materials and uniform oxygen demands throughout the tank.

19.

An advantage of the extended aeration process is that less aeration tank capacity is needed than with conventional activated sludge.

False

✓

True

✓

This is a listed advantage of a activated sludge process modification call contact stabilization and not extended aeration. Contact stabilization is a system of activated sludge treatment in which mixed liquor is aerated in a short (40 min.–2 hr.) period prior to separation of the solids in the final clarifier. Due to the shorter detention time, contact stabilization requires less tank volume than other process modifications.

20.

An advantage of the sequential batch reactor process is that it only requires one tank and no separate clarifier to perform its task.

True

✓

False

✓

Mystery answer C. (It's in the book, so don't blame me.)

✓

This statement is confirmed in Table 8.14: Sequencing Batch Reactor(SBR), however on the subject of "one tank" only one tank is REQUIRED to complete a process cycle however two are normally used to support continuous flow. "There are two major classifications of Sequential Batch Reactor(SBR) units: the Intermittent Flow (IF) or “true batch reactor,” which employs all 5 process steps (fill, react, settle, draw, and idle), and the Continuous Flow (CF) system, which does not follow these steps and, as such, is not a true batch reactor. The IF-SBR accepts influent only at specific time interval. Because this system is closed to influent flow during the treatment cycles, two or more IF-SBR units are normally operated in parallel. One unit is open for flow intake, while the other(s) run through the remainder of the cycles."

21.

The return activated sludge flow is indicated by what letter?

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

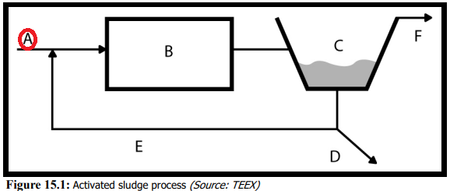

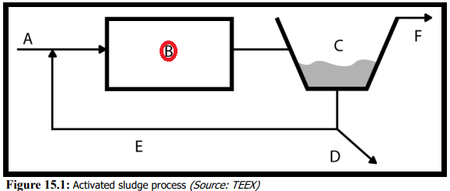

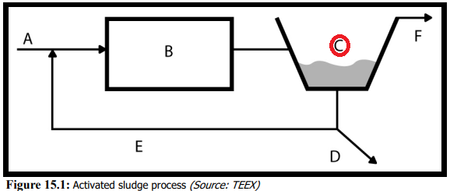

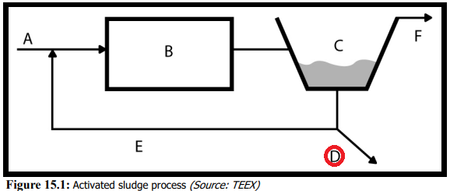

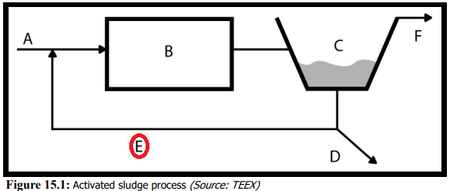

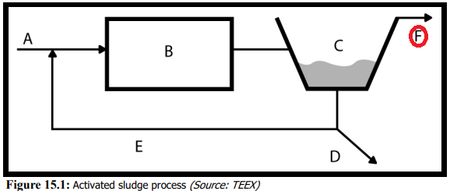

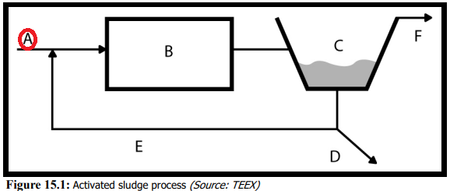

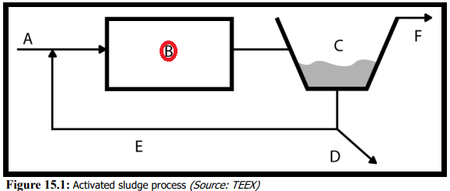

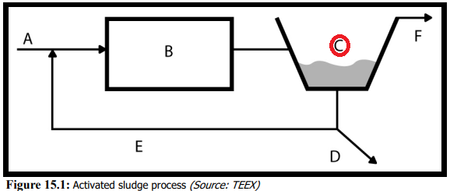

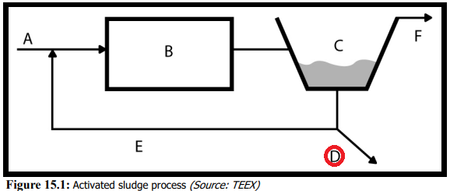

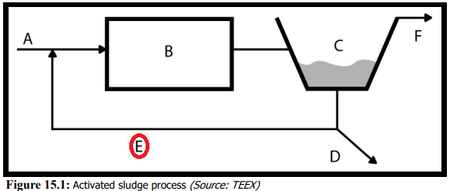

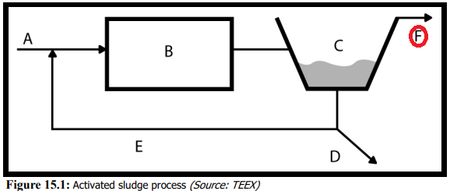

only one path returns anything to any previous portion of the process illustrated below. D would be Waste Activated Sludge(WAS) for removing excess solids and old sludge. E returns activated sludge to the aeration basin to ensure the microorganisms("bugs") are present and sufficient to maintain the digestion process in the aeration basin. A represents your influent and F represents your effluent.

22.

The clarifier is indicated by what letter?

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Only two actual pieces of equipment are shown in the below illustration. B would indicate your aeration basin and C is your secondary clarifier from which your activated sludge is obtained to reseed the aeration process..

23.

What is the relationship between the F/M ratio and the MCRT for a particular plant when the aerator detention time is a constant value?

These two control parameters are unrelated.

✓

When one increases the other increases.

✓

When one increases the other decreases

✓

It is a direct relationship.

✓

Mean Cell Residence Time(MCRT) estimates how long the living cells are kept in the plant. F/M is the ratio of the amount of food applied per day to the microorganisms in the aeration tanks. If we keep all our "bugs" and do not send sludge out through the waste activated sludge path then the residence time of those bacterial cells increases(MCRT ^). the increased population of "bugs" make the "M" in the F/M ratio increase and a given amount of Biochemical oxygen demand(BOD) loading is divided amongst a larger population of "bugs" making the resulting ratio decrease(F/M V). The same is true in reverse and therefore the two values are inversely proportional.

24.

Which of the following are the activated sludge process parameters an operator can change directly?

Aeration rates

✓

Waste rates

✓

The ratio of free-swimming to stalked ciliates

✓

Return sludge rates

✓

Aeration, waste, AND return sludge rates

✓

Aeration, waste, AND return sludge rates can be directly affected by an operator repositioning a valve. Ciliated protozoa (Stalked, free-swimming, and crawling) feed on suspended bacteria and tiny food particles in the water, providing a clearer effluent, and are second in importance to the bacteria in the formation of healthy activated sludge. in order for that to be directly changed by an operator cultured protozoa would have to be manually added and it makes very little sense to do so.

25.

Which of the following happens when the return sludge rate is too low?

The aeration tank will not fill

✓

There will be insufficient organisms to treat the waste load entering the aeration basin

✓

The activated sludge in the aerator will starve

✓

The sludge blanket in the secondary clarifier could become too high

✓

There will be insufficient organisms to treat the waste load entering the aeration basin AND the sludge blanket in the secondary clarifier could become too high

✓

if the return rate is too low the incoming flow is not properly seeded with microorganisms in the for of activated sludge, with a decreased amount of microorganisms less digestion takes place, and since not all of the sludge is being processed more makes it to and collects in the secondary clarifier. If that sludge is neither returned nor wasted the sludge blanket in the clarifier will rise.

26.

Which of the following causes sludge bulking?

Low DO and presence of sulfides

✓

Air supply too low

✓

Organic loading rate too high

✓

Nutrient imbalance

✓

All of the above

✓

Classic bulking is a common settling problem caused by the microorganisms in the mixed liquor. This bulking condition is due to low-density sludge. Studies show that bulking sludges may contain either excessive filaments or slimes. The bacteria that make up activated sludge can be dispersed, floc forming, or filamentous. Activated sludge will usually have a mixture of these types of bacteria, but floc formers need to be dominant for the sludge to settle properly. If there are too many filamentous bacteria, the floc will become fluffy and settle slowly. A bulking sludge develops when conditions in the mixed liquor environment are more favorable to filamentous bacteria than floc-forming bacteria. Filamentous bacteria are like long threads or strings of beads and can grow from one floc mass to another and act as bridges, preventing proper sludge compaction. Low DO, low organic loading, and nutrient deficiencies will favor filamentous bacteria because of their greater surface area. Each cell has its own surface area, unlike floc-forming bacteria, where surface area is limited to the outer surface of the floc mass. Because of their greater surface area, they are more competitive for requirements, such as DO, organic food, nitrogen (N), and phosphorous(P), when resources are limited. Also, some filaments can better use specific conditions, such as septic wastes (organic acids or sulfides) and a low pH.

27.

Testing of mixed liquor indicates the MLSS is 2,000 mg/L, and the settling test shows

that a 1,000 mL sample settles to 250 mL after 30 minutes. What is the SVI and

sludge quality?

50 and too compacting

✓

80 and good

✓

100 and bulking

✓

125 and good

✓

400 and bulking

✓

The "good", "bulking", and "too compacted" quality descriptions in this question refer entirely to the calculated Sludge Volume Index(SVI) numbers. SVI helps the operator know if the sludge is bulky. Numbers between approximately 70 and 150 are typical for healthy activated sludge. Above 150, the sludge gets increasingly bulky and harder to settle. Below 70, the floc does not clump adequately and more suspended solids remain entrapped by the floc as it settles rapidly. SVI = (30 minute settled volume (mL) / MLSS (mg/L)) X 1000 (converts mL to L and mg to g)) = (250mL / 2,000mg/L) X 1000 = 0.125 X 1000 = 125

28.

An old, over-oxidized sludge at an underloaded plant produces mixed liquor solids

that do which of the following?

Settle slowly, but produces a clear effluent

✓

Settle rapidly leaving a turbid supernatant

✓

Reduce nitrification and tend to turn septic if left in the final clarifier too long

✓

All of the above

✓

None of the above

✓

An old sludge will settle rapidly in the first 5 minutes. It will have a granular appearance, compact quickly, and have a ragged surface. Old sludge will leave a cloudy, turbid supernatant that looks ashen or contains tiny floc particles. Colors will be brown to dark brown. Pin floc and ash normally indicate old sludge.

29.

During start-up, your aeration tank produces excessive amounts of billowing white foam.

This can be corrected by ________.

doing nothing; it will go away in a few hours

✓

increasing the sludge wasting rate

✓

seeding the process with sufficient good quality sludge

✓

spraying water on the foam until it is gone

✓

using additional clarifier capacity

✓

This question is referencing Table 8.18: Troubleshooting Guide for Activated Sludge Systems: Foaming Problems and "During start-up" is a key point as "billowing white foam" can be caused by other conditions. The specific corrective action proscribed in this table is to "Return all solids and do not waste until MLSS level comes up to proper range. Seed the process with good quality sludge. Keep DO levels in the 1 to 3 mg/L range.".

30.

A complete mix activated sludge plant has a fast settling sludge and high amounts of pin floc leaving the clarifier. One way to correct this problem is to ________.

increase the RAS flow

✓

reduce wasting rates

✓

increase dissolved oxygen levels

✓

increase the F/M ratio by wasting more

✓

increase the sludge age by wasting less

✓

"Fast settling sludge and high amounts of pin floc leaving the clarifier" indicates old sludge that has been more than sufficiently processed staying in the system. wasting is how we get rid of the stuff we are done with before final dewatering, stabilization, and disposal. the question seems to be specifically referencing Table 8.19: Troubleshooting Guide for Activated Sludge Systems: Secondary Clarifier (Continued) which lists this as the proper corrective action: "Check F/M, MCRT, or sludge age and increase wasting rates by no more than 10% per day to return to optimum conditions."

Comments

No comments yet

New and Popular

Save Your Progress

Texas Waste Water Treatment Study Guide

Quiz series by Mandaris

...

Copyright H Brothers Inc, 2008–2024

Contact Us | Go To Top | View Mobile Site